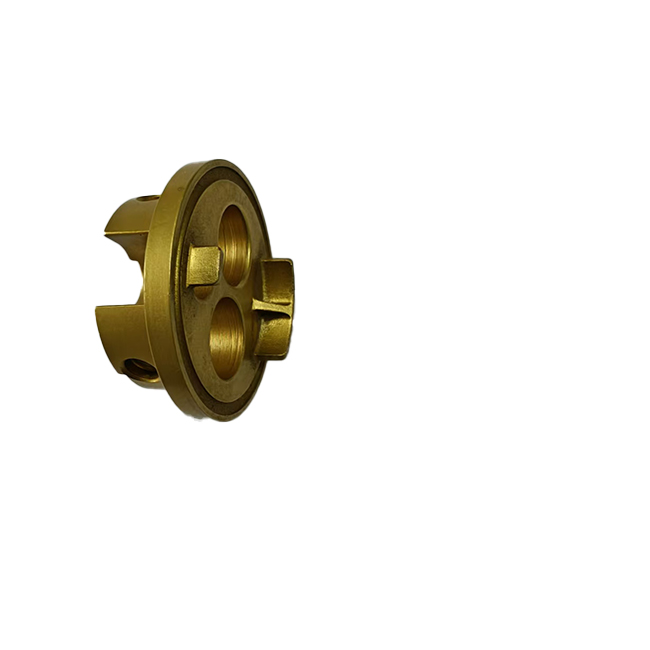

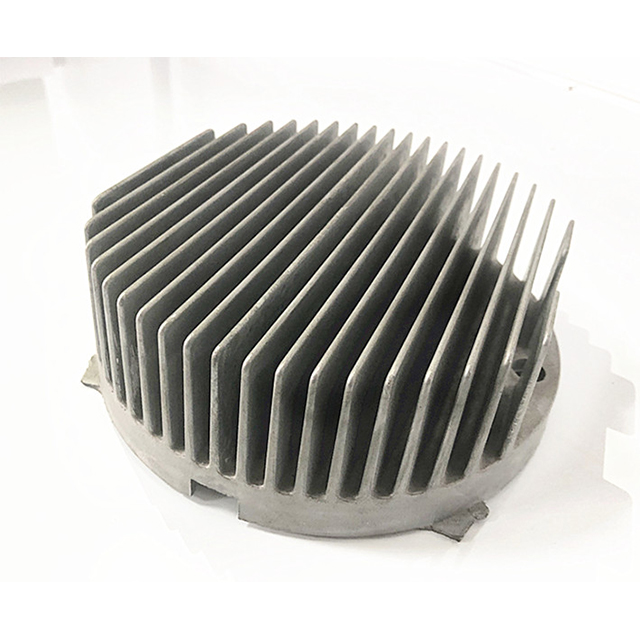

Anodized aluminum die casting products

1,Anode aluminum die-casting products are the most widely used and successful technology, and also the most in-depth and comprehensive technology researched and developed. The anodized aluminum film has a series of superior properties and can meet a variety of needs, so it is called a universal exterior protective film. the film layer has the characteristics of wear resistance, corrosion resistance, sun fast and not easy to fade. No chemical reaction with organic reagents. 2,Aluminum anode principle: aluminum and its alloy in the corresponding electrolyte and maintained process conditions, due to the action of external current, the process of forming a layer of oxide film on aluminum products. 3. At present, the anodizing of aluminum parts is divided into two categories: first, materials containing copper and silicon are very high, such as ZL111 gravity casting materials and ADC12 pressure casting materials, in order to ensure the flow performance of the alloy, the silicon content is generally above 3% 。

- KC

- CHINA

- 2020.6

- 200K

- OD=30MM

- 1000

Details

Anodized aluminum die casting parts are widely used across various industries due to their combination of strength, light weight, and resistance to corrosion. Here's a breakdown of their key details:

1. **Material**

- **Aluminum Alloys**: Commonly used alloys include ADC12, A380, A360, and A413. These alloys offer excellent mechanical properties and ease of casting.

- **Die Casting Process**: Aluminum is melted and injected into a mold under high pressure. The resulting parts are precise and durable.

2. **Anodizing**

- **Purpose**: Anodizing is an electrochemical process that enhances the surface properties of aluminum. It increases corrosion resistance, surface hardness, and provides an aesthetically pleasing finish.

- **Types of Anodizing**:

- **Clear Anodizing**: Offers a natural aluminum look while enhancing protection.

- **Color Anodizing**: Parts can be dyed in various colors (black, red, blue, etc.) during the anodizing process.

- **Thickness**: The anodized layer can vary based on application needs, usually ranging from 5 µm to 25 µm.

3. **Key Features**

- **Corrosion Resistance**: The anodized layer provides excellent protection against environmental elements.

- **Durability**: Die-cast aluminum is lightweight but strong, making it suitable for structural parts.

- **Heat Resistance**: Aluminum has good heat dissipation properties, ideal for parts exposed to heat like automotive or electronics housings.

- **Aesthetic Appeal**: Anodized surfaces can have matte, glossy, or brushed finishes, with a wide variety of color options.

4. **Applications**

- **Automotive Parts**: Engine components, transmission housings, and other lightweight parts.

- **Aerospace**: Lightweight structural components.

- **Consumer Electronics**: Housings for laptops, smartphones, and other devices.

- **Architectural Components**: Window frames, handles, and decorative panels.

- **Medical Devices**: Surgical tools and medical equipment housings.

5. **Advantages of Anodized Aluminum Die Casting Parts**

- **Lightweight**: Aluminum is significantly lighter than steel and other metals, which is beneficial for reducing the overall weight of products.

- **Cost-effective**: Die casting allows for mass production of complex shapes at a relatively low cost.

- **Enhanced Surface Protection**: Anodizing improves the part’s resistance to wear and corrosion.

- **Customizability**: Anodizing offers a wide range of colors and finishes, adding design flexibility.

6. **Surface Treatment Options**

- **Powder Coating**: Provides additional protection and decorative effects.

- **Polishing and Brushing**: Achieve smoother or textured surface finishes before anodizing.

- **Sandblasting**: Creates a uniform matte finish.

7. **Common Quality Standards**

- **ISO 9001**: Quality management systems.

- **ISO 14001**: Environmental management systems.

- **RoHS Compliance**: Restriction of hazardous substances.

- **REACH Compliance**: Ensures materials meet EU chemical safety standards.

If you need further specifications or details about a particular application, feel free to ask!