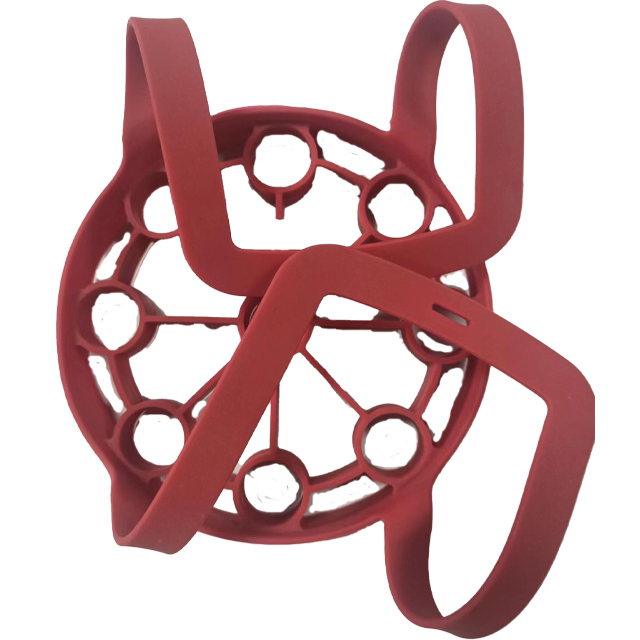

Silicone Products

Product size and characteristics:

A limit size: the thickest place can be 15·20MM, if it is a sphere, it can reach the diameter of 30MM, the general thickness recommended size is not greater than 3MM, when greater than 3MM, it will take more vulcanization time and increase the cost, and the thinnest place can theoretically reach 0.2MM. However, in the design, the thinnest 0.3MM is generally taken, and 0.4MM is recommended.

B Relative size: In the thickness difference, the thinnest and thickest place is recommended not to exceed 3 times. Such problems mainly depend on the temperature and pressure requirements when the material is vulcanized.

C Shrinkage rate: the shrinkage rate of silica gel material is related to the hardness of the material, the secondary material provided by the manufacturer is mostly between 1.022 and 1.042, and the shrinkage rate of 1.03 is generally taken for the material of 40-50 degrees.

D Dimensional accuracy: Because the silicone products are mostly a mold with many holes, the number of holes is very large compared with the plastic products. Therefore, the size control is not so convenient. The general accuracy is plus or minus 0.1, and the high-precision products are plus or minus 0.05. When matching with the holes and keys of the plastic parts, the minimum gap is 0.1 on one side, and the recommended value is 0.2 on one side.