CNC stainless steel products Mercedes-Benz accessories

Precision Engineering: CNC (Computer Numerical Control) machining offers exceptional precision, ensuring that each accessory is crafted with meticulous attention to detail. This precision aligns with the high standards of Mercedes-Benz vehicles, providing a perfect fit for parts like custom emblems, keychains, or pedal covers. High-Quality Material: Stainless steel is known for its durability and resistance to corrosion, making it an excellent choice for automotive accessories. It ensures that these products can withstand exposure to varying weather conditions while retaining their shine and aesthetic appeal. Luxury Finish: CNC machining produces a flawless finish, elevating the look of the stainless steel to match the luxury associated with the Mercedes-Benz brand. The polished or brushed stainless steel surface adds an elegant and modern look to the car's interior or exterior. Customizable Design: CNC machining allows for bespoke customization. Customers can choose accessories tailored to their personal style, such as custom grille badges, exhaust tips, door sill plates, and even steering wheel accents, all with the Mercedes-Benz logo or other personalized designs. Enhanced Performance and Functionality: Beyond aesthetics, CNC stainless steel products can improve functionality, such as with pedals designed for better grip or skid plates for undercarriage protection. These accessories are engineered to complement the performance and longevity of Mercedes-Benz vehicles.

- KC

- CHINA

- 2024 2

- 30K

- L:500MM

- 1

Details

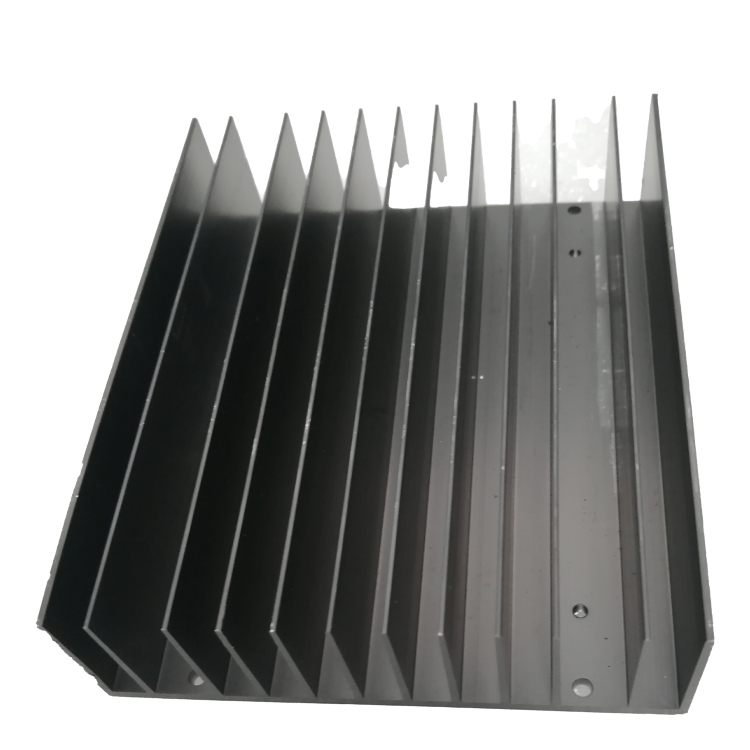

The CNC-manufactured stainless steel chassis products for Mercedes-Benz are designed to offer unparalleled durability, precision, and strength while enhancing the performance and aesthetics of the vehicle. Here's a detailed description:

1. **Precision Craftsmanship**:

CNC (Computer Numerical Control) machining ensures that each stainless steel chassis component is produced with the highest level of precision. This technology guarantees a perfect fit and finish, meeting the exacting standards of Mercedes-Benz. The intricate details, tolerances, and contours of the chassis parts are machined with exceptional accuracy, providing seamless integration with the vehicle’s existing structure.

2. **Superior Material Quality**:

The use of **high-grade stainless steel** ensures robustness, corrosion resistance, and long-term durability. Stainless steel offers excellent resistance to rust, oxidation, and other environmental factors, making it ideal for chassis components exposed to harsh conditions such as moisture, road debris, and varying temperatures.

3. **Enhanced Durability**:

Stainless steel chassis components are built to withstand significant wear and tear, contributing to the longevity of the vehicle. These products are particularly valuable for off-road or high-performance models, where the chassis is subject to extreme stress. The strength of stainless steel ensures that the chassis remains sturdy, providing improved stability and safety.

4. **Improved Structural Integrity**:

CNC stainless steel chassis parts enhance the overall structural integrity of the vehicle. The precision-machined components ensure that the vehicle’s weight is evenly distributed, reducing stress on specific areas and enhancing the vehicle's handling, especially during high-speed driving or challenging road conditions.

5. **Custom Design & Compatibility**:

CNC technology allows for the creation of custom chassis products tailored to specific Mercedes-Benz models, whether for sedans, SUVs, or performance-oriented AMG vehicles. This customization ensures that each part not only fits perfectly but also meets the performance needs of the particular model.

6. **Aesthetic Appeal**:

The stainless steel finish adds a premium look to the underbody of the vehicle. Whether polished to a high shine or given a matte, brushed finish, these chassis components contribute to the luxury image of Mercedes-Benz, even in areas typically unseen. This attention to detail reflects the brand's commitment to quality and craftsmanship.

7. **Enhanced Performance**:

CNC stainless steel chassis parts, such as subframes, crossmembers, and suspension mounts, are designed to improve the vehicle's overall performance. Their precision construction contributes to better suspension response, reduced body roll, and improved road handling, especially in high-performance driving scenarios.

8. **Corrosion Resistance**:

One of the standout benefits of stainless steel is its ability to resist corrosion. This makes it the ideal material for chassis components that are in constant contact with road salts, water, and other corrosive elements. As a result, the chassis remains intact and reliable over time, reducing maintenance costs and prolonging the lifespan of the vehicle.

Conclusion:

CNC-manufactured stainless steel chassis products for Mercedes-Benz combine cutting-edge technology, high-quality materials, and meticulous craftsmanship to deliver parts that enhance both the performance and aesthetics of the vehicle. These products are designed to endure harsh conditions, ensuring the long-lasting structural integrity of the chassis while maintaining the luxury and precision that Mercedes-Benz is known for.